By Geoff Geddes

Editor’s note: The following piece was written for Swine Innovation Porc. For more information, contact Leslie Walsh at lwalsh@swineinnovationporc.ca.

If you want to make a pork producer’s day, you need only utter three words: lower feed costs.

Accounting for 65 to 70 per cent of pig production expense, feed continues to eat away at farmer profits. This is especially true for growing-finishing pigs, as they account for about 80 per cent of all feed consumed.

As producers continue to grapple with thin margins and challenges to sustainability, the timing is perfect for developing cost-effective feeding strategies through projects such as, “Reducing feed cost and the environmental footprint and enhancing global competitiveness of Canadian pork production by increased nutrient utilization of feedstuffs fed to growing-finishing pigs,” supported by Swine Innovation Porc (SIP). The study and its benefits are made possible by financial support from pork producers –something that scientists appreciate at a difficult time for the industry.

“This is a follow-up to some previous projects that looked at reducing costs for growing and finishing pigs using alternative feedstuffs,” said Ruurd Zijlstra, Professor, Department of Agricultural, Food and Nutritional Science, University of Alberta.

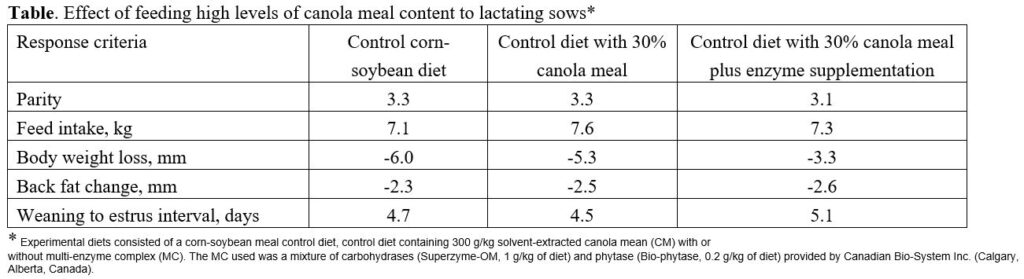

The current study examines how to use enzymes and other technologies to derive more nutrients from those feedstuffs.

“We are hoping to characterize the nutrient value of different feed ingredients that people can use to formulate pig diets more accurately,” said Martin Nyachoti, Professor, Department of Animal Science, University of Manitoba. “In doing so, we can lower feed costs and reduce the environmental footprint. For example, if we avoid feeding pigs more than they require, there will be less nutrient excretion involved.”

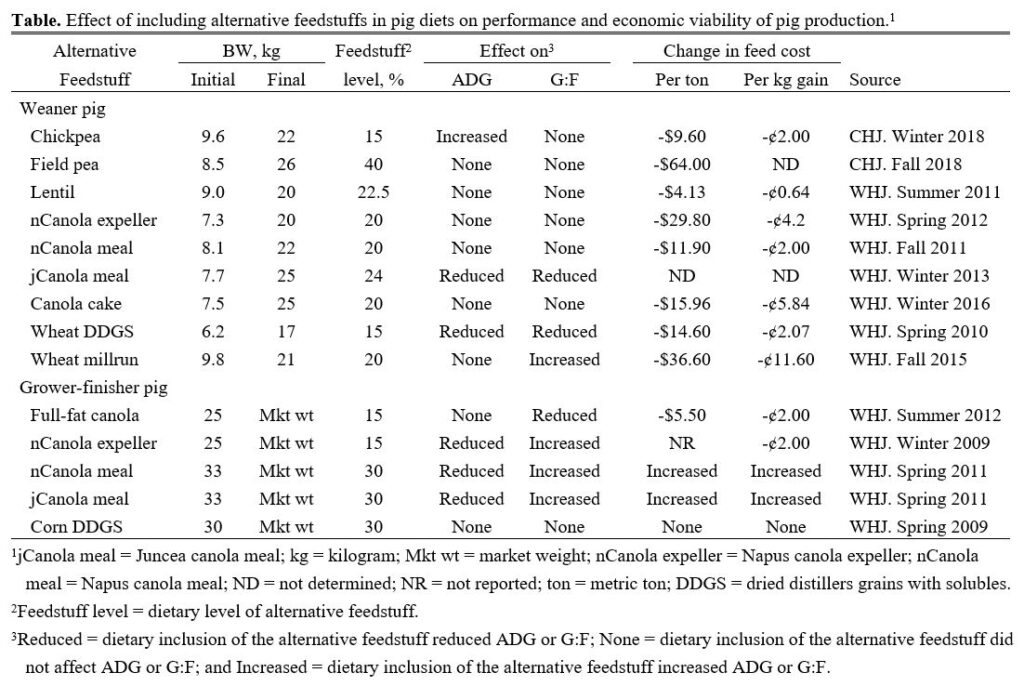

As part of the project, locally available feedstuffs must be considered to meet the nutrient requirements for reducing the feed cost per unit of lean growth.

“To achieve the main goal, locally sourced ingredients need to be characterized, and we must consider opportunities of processing and feed enzymes to enhance nutrient utilization,” said Zijlstra. “Consequently, nutrient losses into the environment and the need to import nutrients into a production system will be reduced in parallel.”

This reduction is important, because excessive discharge of nitrogen and phosphorus in pig manure poses serious environmental concerns that may hamper competitive pork production. Expanding the matrix of well-characterized feedstuffs to formulate swine feed will enhance flexibility in feed formulation. Furthermore, the use of pigs as an omnivorous species to convert co-products into pork will improve the sustainability of pork production.

Central to this study is a nutritive evaluation of Canadian feed crops and their co-products for swine diets. Canada is the world’s largest exporter and one of the world’s largest producers of legume seeds, including pulse grains and soybeans. While soybeans are increasingly grown in Quebec, Ontario and Manitoba, a wide range of pulse grains – including faba bean, field pea, chickpea, lentil and kidney bean – are grown in Ontario and western Canada.

“In general, pulses contain anti-nutritional factors that may reduce the nutritive value of pulses for swine compared to their expected value based on their starch, protein, fibre and fat content,” said Zijlstra. “Clearly, the relationship between anti-nutritional content and nutritive value requires better characterization.”

Initial data from the project that began in 2018 indicates that important differences exist in starch digestibility among feedstuffs, especially for pulse grains. Similarly, differences exist among feedstuffs in fibre fermentability. In addition to pulse grains, short-season corn and small grains – such as oats, triticale and oilseed co-products – are produced in Canada. Research focused on establishing the nutritive value of these feedstuffs for swine is needed to optimize their use in mitigating feed costs.

While strides have been made recently to characterize the nutritional value of Canadian feedstuffs, major gaps remain in North American feedstuff tables, especially for feedstuffs that are unique to Canada.

In spite of COVID-19, the projects are continuing following a brief stoppage. Once life returns to normal, they will target field peas and lentils, then move into oilseed co-products coming from different oil extraction methods. They will also resume analyzing a pile of samples that await their attention.

The unexpected break is frustrating all around, but researchers hope their final results will be worth the wait.

“The greatest benefit from this study will be making nutritionists more comfortable using a wider array of feedstuffs for growing and finishing pigs, which should significantly reduce feed costs,” said Zijlstra.

According to Nyachoti, the project should also “help companies better define and market these feedstuffs.”

Of course, the study and its benefits are made possible by financial support from pork producers, something that scientists appreciate at a difficult time for the industry.