By Treena Hein

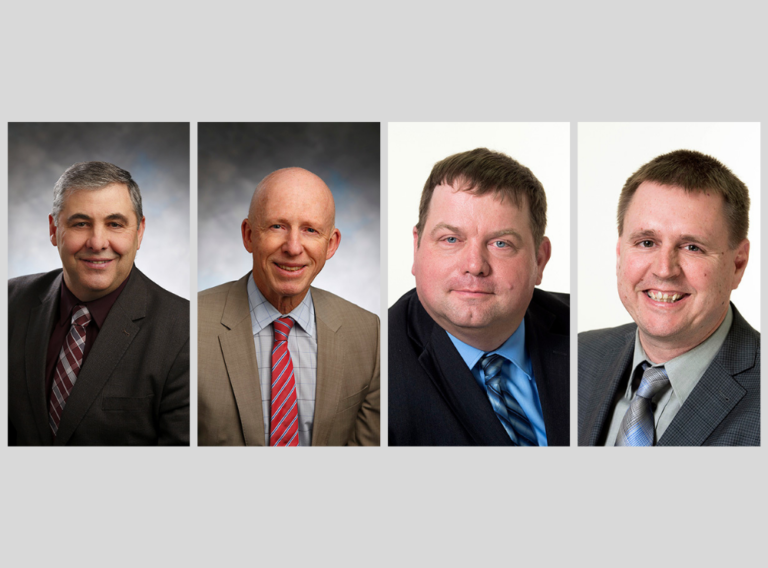

Earlier this year, the Ontario Pork and Manitoba Pork boards of directors welcomed new chairs. In conversation with the incoming and outgoing leaders in both provinces, all four were reached to provide their take on current and future priorities for their respective organizations.

Manitoba priorities include improved pricing

Rick Préjet, Manitoba Pork’s incoming board chair, grew up in Notre Dame de Lourdes – about 130 kilometres southwest of Winnipeg – where he assists his oldest son in running a 5,000-sow farrow-to-finish operation – including nurseries, finishing barns, a feed mill and trucking – which employs more than 40 people. After graduating with a diploma in agriculture from the University of Manitoba, Préjet worked for seven years in the feed industry before returning to Notre Dame with his wife Roseline and their four children to build a 150-sow hog farm, eventually partnering with local investors to build their larger operation, stimulating the local economy in the process.

Préjet is no stranger to the Manitoba Pork board, having already spent a decade serving on it. During six of those years, he led various committees, including human resources and industry performance. He also spent nine years serving on the Prairie Swine Centre board of directors, including several years as chair.

“I’ve always thought research was important,” said Préjet. “The Centre is an arm of the University of Saskatchewan, but financially independent, and that has always been the challenge – to make sure enough grant and producer dollars, as well as income from selling pigs, were coming in. Collaboration was therefore important, reaching out to other research institutions in western Canada and eventually to Ontario and Quebec, to ensure we were not overlapping with study topics. Research funding dollars are limited, and we must all work to stretch them as far as we can.”

In terms of Manitoba Pork’s goals, a top priority for Préjet is to do everything he can to move the western Canadian industry to more equitable pricing formulas with greater weight given to cutout values. Last year, Manitoba Pork and the producer organizations in B.C., Alberta and Saskatchewan approached major packers about the issue, and at this point, some have stepped up. Others, however, have not.

“There’s no quick answer,” said Préjet. “Discussions are ongoing to try and figure out the best plan. We are seeing independent producers continuing to close, because they can’t make enough money to keep going.”

Préjet also wants to focus on further development of collaboration across the value chain: “We’realready doing well with this, and we have a lot of people involved in this collaboration, so it’s a matter of continuing on. It’s about understanding each other’s needs and how we can make the system work for everyone.”

Business risk management is also a priority for Préjet: “We really appreciate the work that the federal agriculture minister and the provinces have done on this, ensuring there are long-term programs going forward that work for our industry.”

In the shorter term, Manitoba Pork staff are now reaching out to municipalities individually, following a discussion with the Association of Manitoba Municipalities, to consider the value of having hog operations in their areas. The Manitoba Pork board wants to inform elected officials and community members about what to expect with new building projects and address inaccurate perceptions.

“We’re also working again with Assiniboine Community College in Brandon on some changes we’d like to see to their pork production training courses,” said Préjet. “And it’s time again for us to do strategic planning as a board. We do this every five years.”

Former Manitoba chair reflects on disease prevention

Préjet takes the reigns from George Matheson, who spent 15 years as a director and six years as the chair of the Manitoba Pork board. During his tenure, a concerted effort to stamp out porcine epidemic diarrhea (PED) in Manitoba has proven very effective. That is, during 2019, the province’s pork producers lost about three per cent of the provincial herd – approximately eight million pigs – to PED, but in 2020, there were only three cases in the province, with none so far in 2021. However, vigilance remains critical, as there are lots of cases this year south of the border.

“It helps that there’s only one major route from the south into the province,” said Matheson. “And there is also lots of distance both west and east to other pork producers.”

Over the years, Matheson also saw relationships with the U.S. pork industry develop significantly: “Things are very good now. Years ago, there were trade challenges, but we’re very integrated now as part of one big system, and I hope that that continues. We’ve kept ASF out, and we’ve got plans in place that should allow for continued exports from some areas of North America in case it’s found in a specific location.”

Matheson thanks the provincial pork industry for its long-standing confidence in him: “A great board and great staff made my job much less stressful.”

Collaboration and growth are key in Ontario

At Ontario Pork, new chair John de Bruyn is settling in. De Bruyn previously served as vice-chair and worked hard to secure support for a new swine research facility in Elora, near the University of Guelph.

“We got the capital investment together and will now have a facility similar to the beef and dairy research barns nearby,” said De Bruyn. “I believe this sends a message to young people and to our trade partners as well that pork is valued in Canada – that it’s an important industry.”

With his wife, Deb, De Bruyn has a 750-sow farrow-to-finish operation near Woodstock, about 50 kilometres northwest of London. Their five children have always contributed to the farm, and the oldest, Drew, has now taken on most of the operational duties. In his youth, De Bruyn graduated with a diploma from the Oxford School of Agriculture at Fanshawe College, and he has been active in Swine 4H and Ontario Pork over the years.

Above all this year, De Bruyn would like to see a return to stronger connections among Ontario’s pork producers: “I think personal interactions are important, and I’m looking forward to that as COVID-19 is taken care of. Online meetings have been good, but it’s very valuable for producers to share information in-person about running their farms. It’s also a way for producers to talk to us about their concerns and what we need as an industry going forward. And we need to build interest in serving on the board.”

De Bruyn also wants to ensure the political structure changes proposed for Ontario Pork prior to the pandemic move ahead. In addition, he wants to nurture sustainable industry growth: “Ontario has everything the industry needs. Lots of water, the best grain in the world, transportation infrastructure, the know-how. Having most of our feed grown here mitigates feed price fluctuations. The challenge is building the export market and ensuring we continue to prevent ASF entry and mitigate the risks of possible entry.”

De Bruyn is confident that Ontario’s pork producers can continue to exceed consumer expectations related to food safety, animal welfare and environmental footprint: “Most of our operations are on 100- or 200-acre parcels, so there’s ample room to handle more manure. We are also well-positioned with the provincial government and agencies like the Thames River Collaboration to continue working on environmental issues, such as phosphorus levels in Lake Erie. It’s a strength of Ontario Pork that we work collaboratively to seek out solutions, and we will continue to use that strength.”

De Bruyn would also like to see more investment in provincial processing capacity: “Right now, we rely on about 20,000 hogs a week being processed in other provinces, and some weaners are finished in the U.S. It would be great to have more processing here.”

Former Ontario chair prides himself on social responsibility

Past Ontario Pork chair Eric Schwindt grew up on a farm near Elmira – just outside of Kitchener – where he and his wife Steph have raised their three daughters. Reflecting on his time as chair: “COVID-19 was certainly challenging. It took a lot of effort from producers, processors, marketers, transporters, Ontario Pork staff and government to keep market hogs moving, demonstrating the resiliency of the industry. Over the longer term, we also worked to build a collaborative approach with government for the continued development of business risk management programs.”

Schwindt thinks the other major accomplishment during his term was advancing the Ontario Pork social responsibility report. It demonstrates to all stakeholders that continued progress is being made to ensure pork is safe, sustainable and healthy, and it has been updated every year since 2015.

“I really appreciate the opportunity to have served as chair of Ontario Pork,” said Schwindt. “All the things I learned, all the people I’ve met, and the friendships – it’s been really fun and interesting.”